Since 2020, the national metrology institute of Germany (PTB) has implemented the ARTICAL II project with the support of stakeholders from the Colombian Quality Subsystem (SICAL) and the National Business Association of Colombia (ANDI). Goal 3 of the project contains strategies for expanding and strengthening quality services for the circular economy in the steel and household appliance sectors. At the request of the Colombian Committee of Steel Producers of ANDI, it has been agreed to promote the transformation of black slag and to reincorporate it into the productive cycle as raw material for the construction industry.

Given the impending shortage of natural sands throughout the world, the use of black slag can be considered especially advantageous given the following key factors: Steel companies are interested in selling black slag, construction industries are searching for new raw materials (artificial aggregates) and the use of black slag instead of sand reduces the environmental impact by preventing the exploitation of quarries, riverbeds, and the seas. Black slag is a co-product derived from electric arc furnace (EAF) steel production.

The use of black slag as a raw material is more recent than that of white slag (a traditional co-product of blast furnace steel). However, several countries – namely, Spain, Japan, Germany, Brazil, and Chile – have already explored its potential for use. In Colombia, research centers and steel and cement companies have explored additional uses for black slag, although no international standards or standardized testing methods exist. According to the results of the PTB study, knowledge of the material is fragmented and there are gaps in measurement traceability and accuracy.

An initial workshop titled Waste to raw material: the contribution of quality services to promote the use of black slag in Colombia was held on May 9 and 10, 2022 at the ICONTEC (Colombian Institute of Technical Standards and Certification) headquarters in Bogotá. Relevant stakeholders in Colombia reviewed the possibilities of using black slag and identified challenges for metrology, standardization, accreditation, and testing laboratories. The meeting was attended by delegates from the following institutions:

- Steel industry companies affiliated with the Colombian Committee of Steel Producers (ANDI)

- Cement industry companies

- Regulatory institutions

- Research and development centers of universities

- Ministry of Commerce, Industry and Tourism (MinCIT)

- Ministry of Environment and Sustainable Development (MinAmbiente)

- Entities of the National Quality Subsystem SICAL, Colombia: National Institute of Metrology (INM), National Accreditation Body (ONAC), Colombian Institute of Technical Standards and Certification (ICONTEC), Superintendence of Industry and Commerce (SIC), National Association of Conformity Assessment Bodies (ASOCEC) and the Institute of Hydrology, Meteorology and Environmental Studies (IDEAM)

The workshop was also attended by representatives from two specialized institutions in Chile: The Superintendency of the Environment (SMA) and the National Institute for Standardization (INN). Two important virtual participants were EcoAZA – a pioneer steel company in the development of the circular economy in Chile – and the Açobrasil institute (Brazil), whose experience includes establishing standards for slag.

The workshop provided a broad exchange among the participants and the consolidation of information in the technical field. The Chilean and Brazilian institutions demonstrated advances in standardization development and in experiments for the use of black slag as an input in the production of concrete.

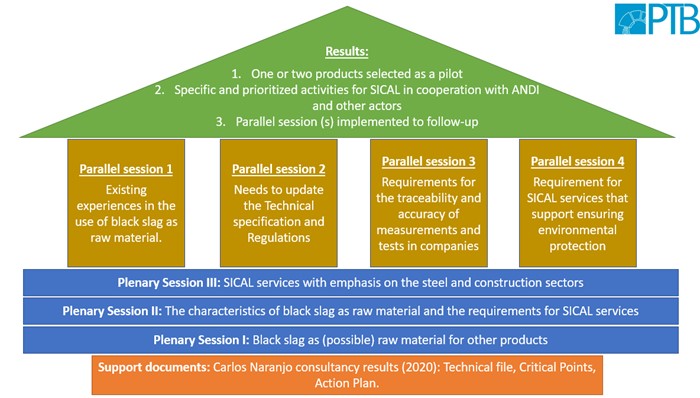

The workshop combined plenary and parallel sessions (see Figure 1) focused on defining economically viable products that can be produced with black slag, and reviewing the requirements for metrology, standardization, and accreditation. The main objective was to ensure the reliability and comparability of measurements in first- and third-party laboratories both for the processes in individual companies and for environmental protection measures.

What were the most important results and conclusions of these two days in Bogota?

- Black slag is a raw material with great potential for use in the construction industry in a global context in which natural sands are increasingly scarce.

- Despite a series of experiments to apply black slag in road construction, cement and concrete production, sufficiently stable and reliable results are still needed in order to begin large-scale application.

- It is necessary to better define the physical, chemical, and mechanical characteristics of the black slag produced and its suitability for manufacturing construction materials. Improvements in measurement accuracy and traceability such as the standardization of cooling and storage methods require coordinated activities by SICAL in cooperation with industry and research and development centers.

- The application of black slag as an input for the construction sector also requires new regulations and environmental tests.

- The definition of a product as a pilot for the ARTICAL II project depends on various criteria such as the available volume of black slag, its physical and chemical characteristics, transportation costs, and the viability of developing new technical standards and regulations that guarantee the safe use of black slag as a new raw material. This challenge is to be solved in cooperation with the steel industry companies (ANDI).

The participants expressed their satisfaction with the relevance of the workshop and its results. In line with the primary objective above, participants also communicated their interest and willingness to participate in other workshops and support the activities related to the implementation of the project.

Cover Image © istock